- Sampling

- Open mold

- Raw materials

- Mixed powder

- Forming

- Sintering

- Post-process

- Packaging

- Shipment

Hualian has 50 sets of China's most advanced powder metallurgy automatic forming machines, all of which are equipped with automatic arrangement functions. The output per shift can reach 300,000 pieces, and the saturated output per day can reach 500,000 pieces.

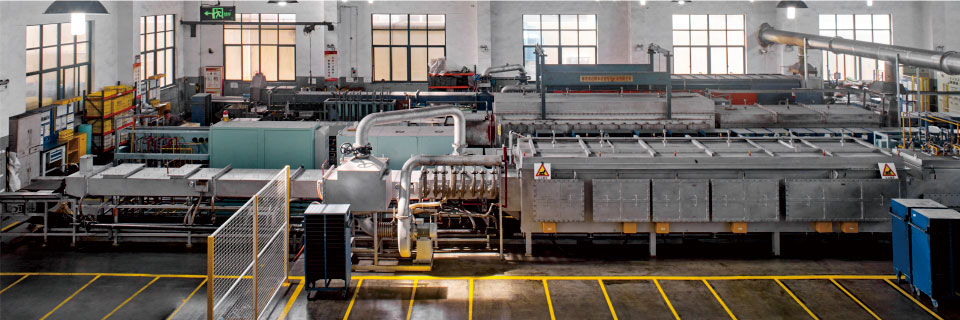

Using Yuchuan high temperature push rod furnace, the highest sintering temperature can reach 1300°C. At present, the single-day sintering capacity of the four sintering furnaces reaches 10 tons/day.

At present, the workshop has three automatic groove and ring lines, 2 automatic chamfering machines with a monthly output of 800,000 pieces, a semi-automatic driving wheel torque machine with a monthly output of 1 million pieces, and 18 single-machine CNC and transmission instruments , The monthly output of bench drills can reach 300,000 pieces.

The Hualian Packaging Workshop introduces an advanced glass plate image screening machine, uses industrial cameras to image the detected object, and then uses image processing to analyze the image to determine whether the detected object meets the set parameter index and realize the test Automatic detection of objects, thereby reducing labor costs, reducing human detection errors, and greatly improving the quality of product shipments.

Sophisticated equipment and facilities are the foundation of an enterprise's comprehensive strength, and only first-class equipment can produce first-class products. With more than 20 years of diversified manufacturing experience, the company has possessed continuous process improvement and innovation capabilities. Today, Hualian has realized the control of the manufacturing process and technology of the full range of products. There are five workshops in the company, namely mold, pressing, sintering, machining, and packaging, all using domestic and foreign first-line brand equipment.